|

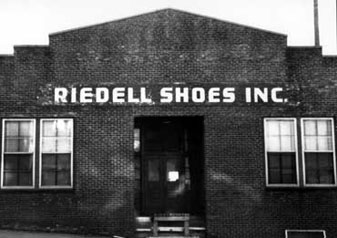

Riedell Shoes Inc. was founded in Red Wing, Minnesota 60 years ago by Paul Riedell and his wife Sophie. With the blessing of his former employer, Red Wing Shoe Co., Paul embarked on developing comfortable, quality skating boots and the legend of Riedell began. Paul, a member of both the ice and roller skating Hall of Fame, is credited with making recreational skating widely available to children, teens and adults through the creation of comfortable, affordable skates. Riedell Shoes Inc. was founded in Red Wing, Minnesota 60 years ago by Paul Riedell and his wife Sophie. With the blessing of his former employer, Red Wing Shoe Co., Paul embarked on developing comfortable, quality skating boots and the legend of Riedell began. Paul, a member of both the ice and roller skating Hall of Fame, is credited with making recreational skating widely available to children, teens and adults through the creation of comfortable, affordable skates.

Today, Paul’s grandsons Bob, Dan, Scott and Paul Riegelman

along with 100 skilled employees manufacture the most complete line of figure skates available in the world. Riedell also manufactures hockey, speed, roller and in-line skates. Riedell skates are distributed internationally.

From the beginning, Riedell knew fit was essential for both skating enjoyment and top performance. In the early days, Paul Riedell borrowed a friend’s medical books to study the structure and movement of feet. Combined with his knowledge of skating, he developed the skating shoe design that accommodates the skater’s motions on the ice. From the beginning, Riedell knew fit was essential for both skating enjoyment and top performance. In the early days, Paul Riedell borrowed a friend’s medical books to study the structure and movement of feet. Combined with his knowledge of skating, he developed the skating shoe design that accommodates the skater’s motions on the ice.

The manufacturing process for building figure and hockey skates is labor intensive and involves as many as 125 different production steps.

First, all skates go through the cutting department to cut the leather that will eventually make up the overall skate. The fitting department then provides all the necessary stitching and cementing to put together the components that will make up the overall upper of the skate. From fitting the skate moves to the lasting department where the upper is shaped around the last. (The last is a molded foot formation that gives the skate consistent shape, size, width and dimension.) This process is one of the most important when building skates as it will determine the overall sizing of the skate.

The final step in the process of manufacturing is the bottoming and finishing department. The skate bottom and outsole are prepared and the outsole and heel are then attached and trimmed to match the size and width of the skate. Finally, the skate is ready for cleaning, polishing, final inspection and packing. The final step in the process of manufacturing is the bottoming and finishing department. The skate bottom and outsole are prepared and the outsole and heel are then attached and trimmed to match the size and width of the skate. Finally, the skate is ready for cleaning, polishing, final inspection and packing.

A high quality skate is just the first step. Obviously, no two feet are the same, so Riedell developed the “Diercks Device” fitting scale. Through a nation-wide network of authorized dealers trained at fitting skates, Riedell helps match its customers’ feet with the right skate. “Improper fit is the number one cause for skate failure and poor performance,” said Bob Riegelman, president of Riedell. “Fit is vitally important for any skater and especially for young children. Parents should resist the temptation to buy skates to grow into.”

|